The hardware and software solution is designed to automate the work of mobile personnel carrying out maintenance and repair of equipment (MRO) at enterprises, shops, banks and other organizations.

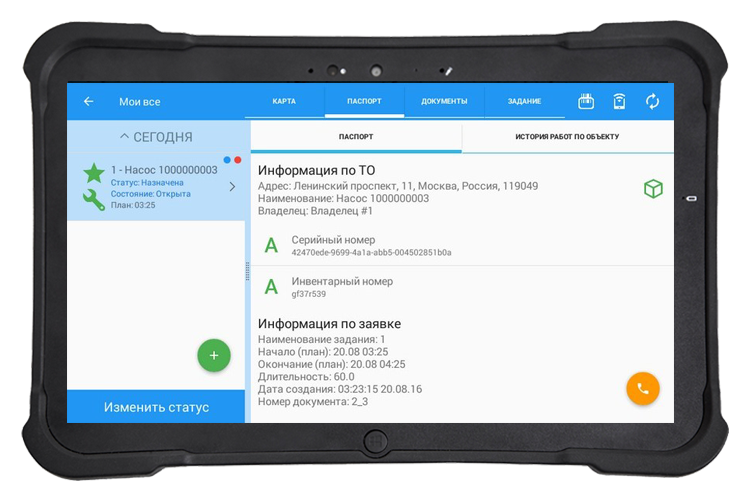

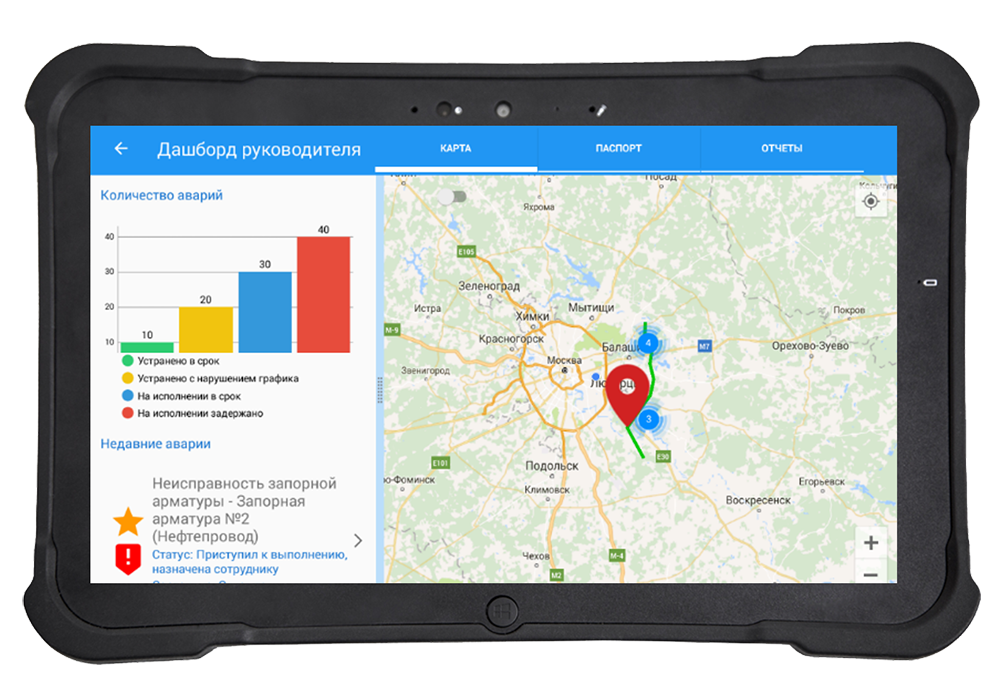

The solution consists of server software and a mobile client running on ruggged handhelds, smartphones and tablets (OS Aurora, Android), provides planning and optimal distribution of MRO applications and control of work performance.

Key Benefits

Improving the quality of performing major scheduled repairs and MRO.

Reduced production losses from downtime

Decrease in the volume of purchases of materials and spare parts.

Ensuring 100% compliance with safety requirements.

Key Features

- Comprehensive long-term and operational planning of inspections and repairs.

- Work on the script.

- Accounting for standards (for all operations, details, etc.).

- End-to-end location control, including linking to key operations.

- Accounting for the consumption of materials and spare parts.

- Accumulation and analysis of collected data.

- Monitoring the implementation of inspections by RFID, NFC, QR codes on equipment.

- Transfer of task / key operations statuses to the IT system.

- Photo and video recording of the results of work, defects and other operations.

- Convenient access to the necessary information (reference data, work history, documentation, instructions, etc.).

- Support for mobile OS Aurora, Android.

Related Software

Optimum Mobile Workers Management System (Optimum MWMS)

Bogdanov K.I., deputy CEO for IT