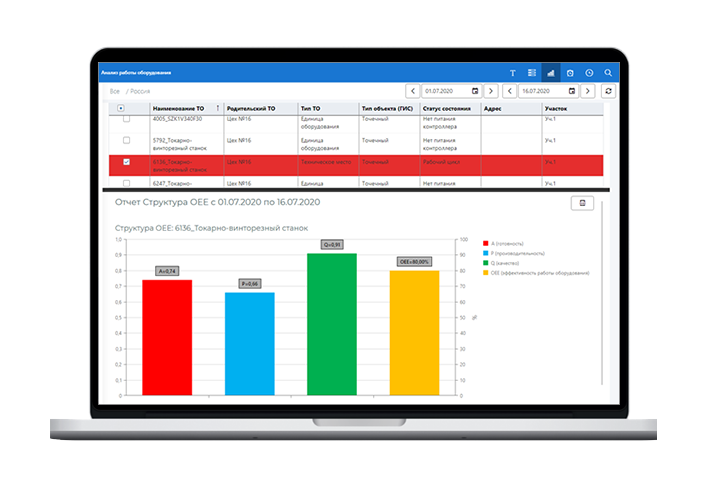

The hardware and software solution is designed for continuous remote monitoring of the operation of production equipment (machine tools, transformers, compressors, etc.) based on the readings of sensors installed on it, industrial Internet of things (IIoT) technologies and artificial intelligence.

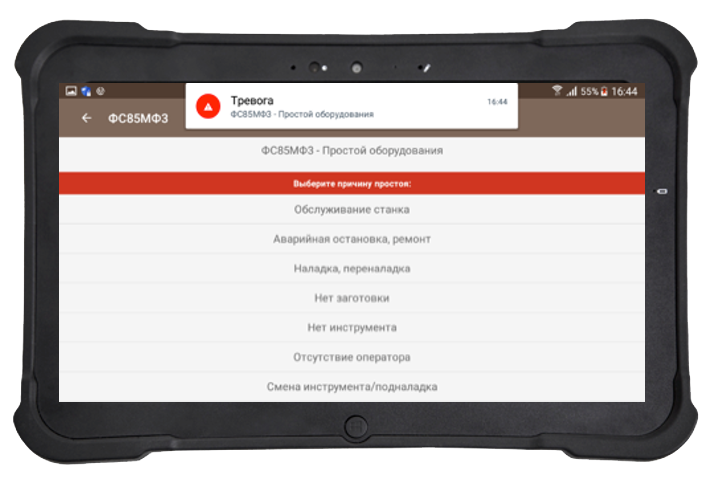

The solution consists of server software and a mobile client running on secure data collection terminals, smartphones and tablets (OS "Aurora", Android), allows you to analyze sensor readings and predict equipment operation, prevent downtime, and increase service life due to timely repair.

Key Benefits

Remote monitoring of the condition of industrial equipment.

Data transmission from sensors wireless or wired (MBee, LTE, Private LTE, GSM, Wi-Fi, LAN).

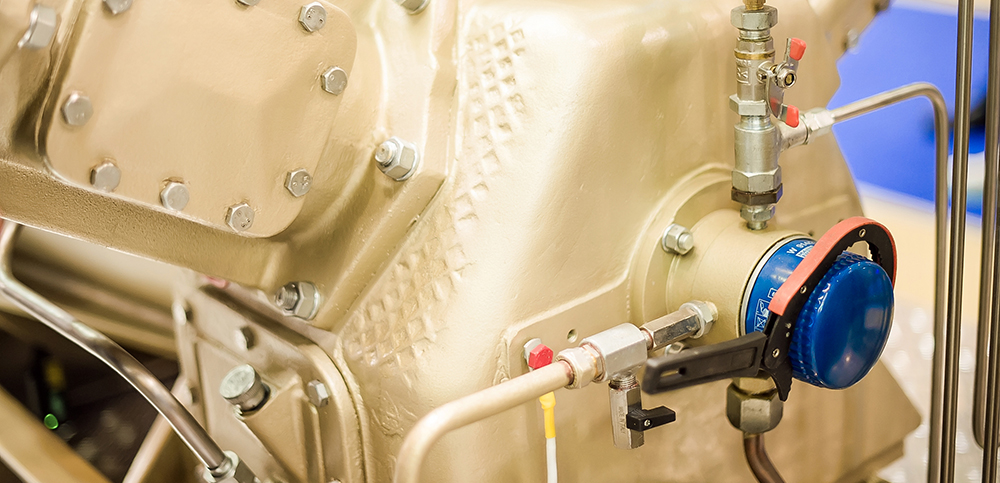

Own development and production of modules for collecting and transmitting sensor readings.

Installation of sensors without tapping into the casing or rack of the CNC machine tool (the equipment manufacturer's warranty is not violated).

Key Features

- Receiving data from sensors in online mode (in special cases with the possibility of accumulating in case of emergency shutdown / lack of communication).

- Formation of a "chain of help". Escalation of equipment downtime problems.

- Real-time monitoring of indicators and equipment condition.

- Objective monitoring and analysis of staff working time.

- Possibility of quick connection of the MRO control unit (field repair crews).

Related Software

Optimum Equipment Monitoring System

F. A. Buzhov, Project Manager, Equipment Monitoring System, Kirovsky Zavod